Detalhes rápidos

Condição: Nova

Tensão: AC380V / 220V

Dimensão (L * W * H): 1500 * 3040 mm

Peso: 980KGS

Certificação: CE

Garantia: um ano

Serviço pós-venda prestado: engenheiros disponíveis para prestar assistência a máquinas no exterior

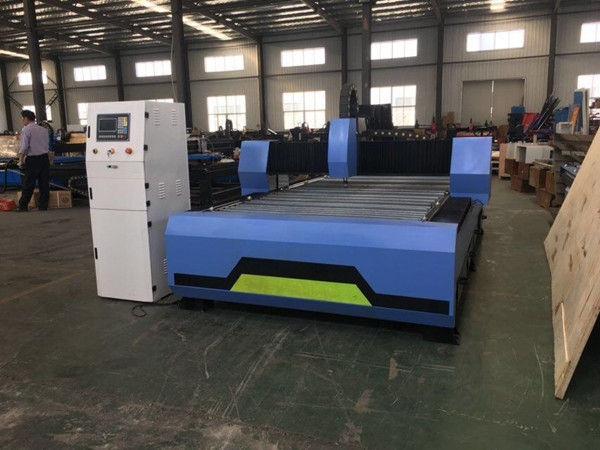

Produtos: Grande máquina de corte de chapa de aço inoxidável OP1530

Área de trabalho: 1500 * 3000 mm

Tamanho da mesa: 1700 * 3540 mm

Motor de controle de 3 eixos: motor de passo

Repetibilidade: +/- 0,02 mm

Velocidade de corte: 8m / min

Potência do plasma: 60A, 100A, 120A, 200Aetc

Tensão de trabalho: 380v / 220v, 3 frases

Espessura de corte: 0,3-40 mm

Linguagem de comando: código G

Máquina de corte a plasma CNC Parâmetros

| Viagem do eixo X, Y | 1300 * 2500mm |

| Dimensão do Corpo | 1500 * 3040 mm |

| Potência do plasma | 60A, 100A, 120A, 200A etc EUA Hypertherm |

| Estrutura da Tabela | mesa de aço refratário especial de plasma + lâmina de 6mm |

| Repetibilidade | +/- 0,02 mm |

| velocidade de trabalho | 8m / min |

| Máx. Velocidade de viagem rápida | 30m / min |

| Espessura de corte | 0,3-40 mm |

| Sistema transversal | Guia linear em 3 eixos |

| Controlador | Iniciar o controlador (com controlador de altura THC) |

| tensão de trabalho | 380V / 220V, 3 frases |

| linguagem de comando | Código G |

Máquina de corte a plasma CNC Características

1 Cama de torno soldado de aço perfilado de parede espessa, mais sólida e estável.

2 Projeto de mesa de torno razoável, chapas de aço de 10 mm de espessura fixadas na mesa de torno coberta por bainha fundida com pontas. As chapas de aço não serão danificadas, mesmo sob chamas violentas. A diferença de nível de toda a plataforma de dois andares permanece em 0-1,5 mm.

3 Motor de passo de alta qualidade e transmissão de rack de alta precisão. Baixo ruído, movimento coordenado estável e preciso.

5 controlador de mão offline DSP; Software Type3 e Ucancam com função de economia automática de material.

6 Configuração padrão: gerador de plasma Fuli 100A, que pode cortar placas de metal de 10 mm.

7 A melhor escolha para todos os tipos de materiais com diferentes espessuras e corte heterotípico de chapas.

Controle de altura de capacitância

A tecnologia avançada de calibração linear de altura faz com que o bico de corte e a placa de corte fiquem entre 3 ~ 30 mm no controle automático de altura no modo de capacitância;

Calibração de linearização simples e conveniente

A função "Uma tecla para calibração de altura" garante que em qualquer circunstância, o usuário só precisa pressionar uma tecla, ele pode calibrar a medição de altura absoluta e obter uma medição de altura linear.

Sistema de controle OMNI THC capaz de

1. Executar controle de velocidade de canto e controle de altura,

2. Restauração de breakpoint, recuperação automática de power-back e memória de breakpoint automática,

3. Recurso especial de usinagem de linha curta com base em um curso suave, extensivamente aplicável a moldagem de metal, bem como publicidade

4. Projeto de descarga inclinado de material avançado. Todas as peças de trabalho acabadas e fragmentos deslizam para dentro do túnel para uma coleta segura e conveniente.